In today’s fast-paced world of online business, global supply chains, and ever-increasing customer demands, warehouse operations are at a pivotal juncture. The need for more efficient, scalable, and cost-effective solutions has driven innovation in warehouse management. Traditional manual processes are being replaced by cutting-edge technologies that streamline workflows, improve accuracy, and reduce operational costs. As businesses strive to meet growing expectations for faster delivery and lower operational costs, warehouse automation is emerging as a game-changer.

1. Robotic Process Automation (RPA) and Autonomous Robots

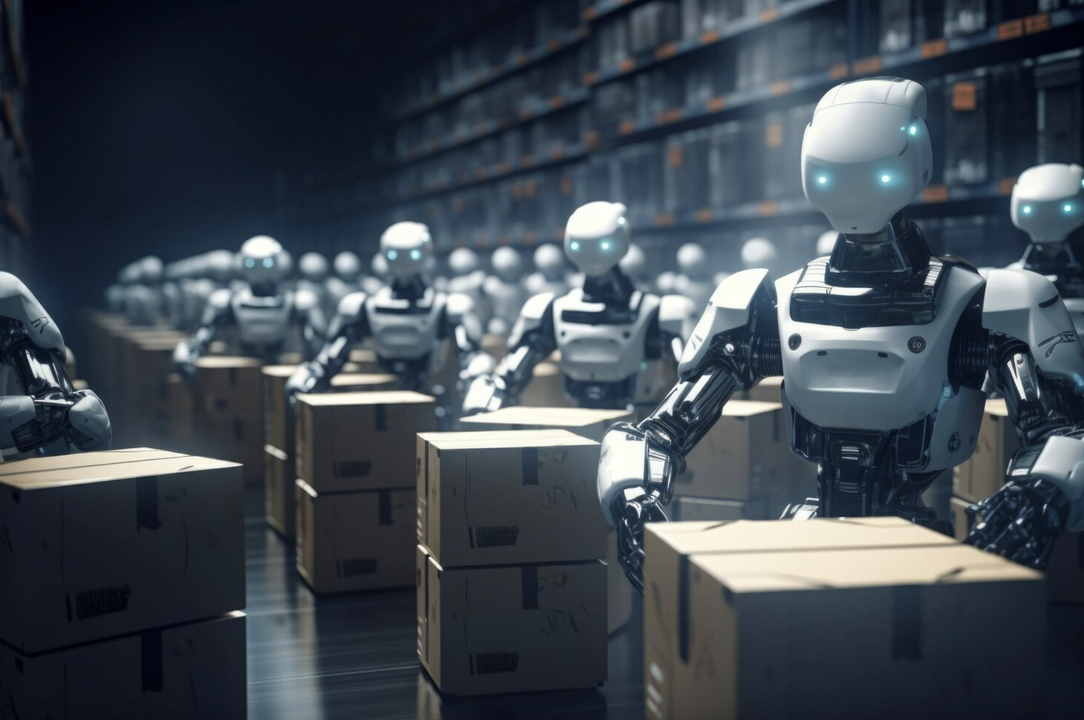

Robotic Process Automation (RPA) is transforming warehouses by automating tasks that were traditionally manual, such as picking, sorting, and packaging. Autonomous robots are becoming a common sight in warehouses, performing tasks with speed and accuracy far beyond human capacity. These robots can work 24/7 without fatigue, reducing the need for manual labor and improving productivity.

Autonomous mobile robots (AMRs) are particularly noteworthy. They navigate warehouse floors independently, moving goods from one location to another, minimizing the time workers spend walking from shelf to shelf. Coupled with automated guided vehicles (AGVs), these robots enable seamless transportation of goods, optimizing workflows and freeing up employees to focus on more complex tasks that require human intelligence.

A perfect example of the impact of robotics is seen in companies like Amazon, which utilizes its robotic fleet to move goods through its fulfillment centers at lightning speed. This level of automation not only speeds up processes but also reduces the risk of human error, leading to improved accuracy and fewer mistakes in order fulfillment.

2. Internet of Things (IoT) for Real-Time Tracking and Monitoring

The Internet of Things (IoT) is another game-changing technology that is enabling smart warehouses. IoT devices, such as sensors, RFID tags, and GPS trackers, are embedded into warehouse assets, products, and equipment. These devices generate real-time data that can be analyzed to optimize inventory management, improve asset utilization, and enhance visibility across the entire supply chain.

For example, IoT-enabled sensors can track the location and condition of goods in real-time, helping to monitor temperature-sensitive items or valuable assets. This allows warehouse managers to proactively address potential issues, such as inventory shortages or equipment malfunctions, before they impact operations.

Additionally, IoT allows for better coordination between warehouse management systems and other business operations. The real-time data generated by IoT devices can be integrated into predictive analytics tools, enabling smarter decision-making and inventory planning. This creates a highly responsive and agile warehouse environment where managers can instantly address changes in demand or unexpected disruptions.

3. Artificial Intelligence (AI) and Machine Learning (ML)

AI and machine learning are taking warehouse automation to the next level by introducing predictive capabilities and smarter decision-making. AI-powered systems can analyze historical data to forecast demand, optimize storage configurations, and predict maintenance needs. This reduces the chances of stockouts, minimizes waste, and helps companies anticipate trends, allowing them to stay ahead of demand.

One of the key applications of AI in warehouses is predictive maintenance. By analyzing data from equipment sensors and monitoring patterns, AI can predict when machinery is likely to break down, enabling warehouse operators to perform maintenance before a failure occurs. This not only reduces downtime but also extends the lifespan of expensive warehouse equipment.

Machine learning algorithms are also used to improve product picking processes. By analyzing previous picking patterns, AI systems can determine the most efficient way to organize items in the warehouse to reduce travel time and improve overall productivity. Over time, these systems “learn” to become more efficient, adjusting based on real-time data to optimize workflows further.

4. Drones for Inventory Management and Surveillance

Drones are becoming a popular tool for inventory management in large warehouses. These unmanned aerial vehicles (UAVs) can fly through warehouse aisles, scanning barcodes and RFID tags to update inventory in real-time. Drones significantly reduce the time and labor required for manual stock counting, enabling more frequent and accurate audits of inventory levels.

Additionally, drones equipped with cameras can perform surveillance tasks, monitoring the warehouse for potential hazards or security breaches. Their ability to access hard-to-reach areas provides an added layer of safety and security, further enhancing operational efficiency.

As drone technology continues to advance, we can expect to see even more use cases in warehouses, including automated restocking, real-time condition monitoring, and even delivery of small goods within the warehouse.

5. Augmented Reality (AR) for Enhanced Picking and Training

Augmented reality (AR) is revolutionizing the way workers interact with their environment in the warehouse. AR glasses or headsets can display real-time instructions, guiding warehouse staff through tasks such as picking and sorting. This helps workers complete tasks more accurately and efficiently, reducing the chances of human error.

For instance, AR-enabled picking systems can display visual prompts that direct workers to the correct shelf and item location, eliminating the need for paper-based pick lists and minimizing travel time. In fast-moving environments, this technology can be a game-changer, improving productivity and reducing order fulfillment times.

Moreover, AR is playing an important role in warehouse training. New employees can use AR systems to get up to speed quickly, receiving hands-on guidance without the need for lengthy training sessions. This reduces the learning curve and ensures that workers are productive sooner.

6. Advanced Warehouse Management Software (WMS) Integration

While the focus here is on automation technologies, it’s important to mention how software systems, such as Warehouse Management Software (WMS), play a critical role in orchestrating these technologies. Advanced WMS integrates with robotics, AI, IoT, and other technologies to provide a centralized platform for managing warehouse operations. These systems help optimize inventory control, track shipments, and ensure real-time visibility into warehouse activities.

WMS solutions are evolving with the rise of automation technologies, offering enhanced features like predictive analytics, real-time tracking, and AI-driven recommendations for inventory replenishment and order fulfillment. These integrations create a highly automated and efficient warehouse ecosystem, where technology and software work together to improve operations.

Conclusion

As the e-commerce industry continues to grow, the pressure to deliver faster, more accurate, and cost-efficient solutions has never been greater. Warehouse automation technologies like robotics, AI, IoT, drones, and AR are making significant strides in addressing these challenges, reshaping warehouse operations across industries. The integration of these technologies not only increases operational efficiency but also enhances customer satisfaction by enabling faster deliveries and more accurate order fulfillment.

Looking ahead, we can expect even greater advancements in automation, as new technologies emerge and evolve. Warehouse automation is not just a trend but the future of supply chain management, and those who embrace these technologies will be well-positioned to thrive in an increasingly competitive market. The future of warehousing is automated—and it’s happening now.

Keep an eye for more news & updates on Gossips!