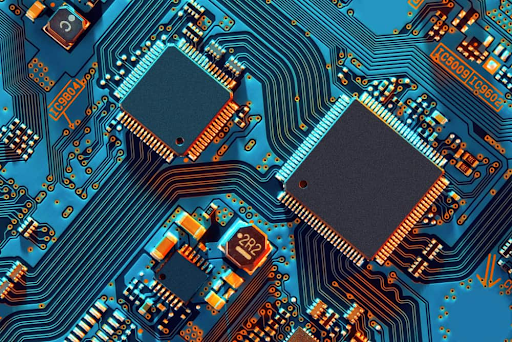

In the intricate world of electronics, achieving PCB perfection is a critical factor in ensuring the reliability and performance of electronic devices. For nearly two decades, JHDPCB has been at the forefront of PCB manufacturing, leveraging extensive experience and advanced equipment to deliver high-quality PCBs. This article explores how JHDPCB’s 18 years of expertise and cutting-edge technology contribute to PCB perfection, with a focus on understanding PCB components abbreviations, PCBA terminology, and PCB packaging terminology abbreviation.

The Journey of 18 Years in PCB Excellence

JHDPCB’s journey over the past 18 years has been marked by a commitment to quality and innovation. The company’s longevity in the industry is a testament to its ability to adapt to changing technologies and maintain high standards in PCB manufacturing.

- Continuous Improvement and Adaptation

Over the years, JHDPCB has continuously improved its processes and adopted new technologies to stay ahead of industry trends. This includes investing in state-of-the-art equipment and adopting best practices to ensure the highest standards of PCB manufacturing. The company’s ability to adapt to advancements in technology and evolving customer needs has been key to its sustained success.

- Expertise in Complex Designs

JHDPCB’s extensive experience enables it to handle complex PCB designs with ease. The company’s skilled team of engineers and technicians are well-versed in the intricacies of PCB design and manufacturing. Their expertise ensures that even the most challenging designs are executed with precision, meeting the specific requirements of various applications.

- Commitment to Quality

Quality is at the heart of JHDPCB’s operations. The company adheres to rigorous quality control measures to ensure that every PCB meets the highest standards. This includes comprehensive testing and inspection processes to detect and address any potential issues before the PCBs reach customers.

Advanced Equipment for Superior Manufacturing

The use of advanced equipment is crucial in achieving PCB perfection. JHDPCB’s investment in cutting-edge technology enhances its manufacturing capabilities and ensures that every PCB is produced to the highest standards.

- State-of-the-Art Fabrication Technology

JHDPCB employs the latest fabrication technology to produce high-quality PCBs. This includes advanced etching, drilling, and plating equipment that enables precise and efficient production. The use of high-resolution imaging and automated processes ensures that PCBs are manufactured with tight tolerances and accurate specifications.

- Automated Inspection and Testing

Automated Optical Inspection (AOI), X-ray inspection, and In-Circuit Testing (ICT) are integral to JHDPCB’s quality control process. These advanced inspection techniques allow for thorough examination of PCBs to identify any defects or issues. Automated testing ensures that every PCB meets the required performance and reliability standards.

- Advanced Assembly Capabilities

In addition to fabrication, JHDPCB offers advanced assembly capabilities, including Surface Mount Technology (SMT) and Through-Hole Technology (THT). The company’s sophisticated assembly equipment ensures precise placement and soldering of components, contributing to the overall quality and performance of the final product.

Understanding PCB Terminology

To appreciate the precision and quality of JHDPCB’s PCBs, it’s helpful to understand some key terminology used in PCB manufacturing and assembly. This includes PCB components abbreviations, PCBA terminology, and PCB packaging terminology abbreviation.

- PCB Components Abbreviations

PCB components are often identified by abbreviations that denote their function and specifications. Common abbreviations include:

- R: Resistor

- C: Capacitor

- L: Inductor

- Q: Transistor (or MOSFET)

- D: Diode

- U: Integrated Circuit (IC)

These abbreviations are used in PCB schematics and design files to identify and specify components.

- PCBA Terminology

PCBA (Printed Circuit Board Assembly) refers to the process of assembling electronic components onto a PCB to create a functional circuit. Key terms in PCBA include:

- SMD (Surface-Mount Device): A type of component designed to be mounted directly onto the surface of the PCB.

- THT (Through-Hole Technology): A technique where components are inserted through holes in the PCB and soldered on the opposite side.

- Reflow Soldering: A process used to solder surface-mount components by heating the solder paste to its melting point.

Understanding PCBA terminology helps in comprehending the complexities of the assembly process and the various methods used to create functional electronic devices.

- PCB Packaging Terminology Abbreviation

PCB packaging terminology refers to the various methods used to package and protect PCBs during manufacturing, assembly, and shipping. Common abbreviations include:

- T&R (Tape and Reel): A packaging method where components are placed in a tape and reel format for automated assembly.

- BGA (Ball Grid Array): A type of IC package with an array of solder balls for mounting onto the PCB.

- QFP (Quad Flat Package): A type of IC package with leads on all four sides, used for surface-mount applications.

These packaging methods ensure that PCBs and components are handled safely and effectively throughout the manufacturing and assembly process.

The JHDPCB Approach to Ensuring PCB Perfection

JHDPCB’s approach to ensuring PCB perfection involves a combination of experience, advanced equipment, and a commitment to quality. By leveraging its 18 years of industry experience and investing in cutting-edge technology, the company delivers PCBs that meet the highest standards of performance and reliability.

- Expert Design and Engineering

JHDPCB’s team of experienced engineers and designers work closely with clients to ensure that every PCB design is optimized for performance and manufacturability. Their expertise in handling complex designs and understanding industry-specific requirements contributes to the success of each project.

- Rigorous Quality Control

The company’s rigorous quality control measures, including automated inspection and testing, ensure that every PCB meets the required specifications. This commitment to quality is reflected in the reliability and performance of JHDPCB’s products.

- Advanced Manufacturing Technology

By utilizing state-of-the-art manufacturing equipment and adopting best practices, JHDPCB maintains a high level of precision and efficiency in its production processes. This advanced technology supports the company’s goal of delivering high-quality PCBs that meet the needs of diverse applications.

Conclusion

JHDPCB’s 18 years of experience and investment in advanced equipment underscore its commitment to ensuring PCB perfection. By adhering to industry standards and leveraging its expertise, the company delivers high-quality PCBs that meet the highest levels of performance and reliability. Understanding PCB components abbreviations, PCBA terminology, and PCB packaging terminology abbreviation provides valuable insight into the complexities of PCB manufacturing and assembly.

For more information on how JHDPCB can support your PCB needs and ensure the highest quality standards, visit jhdpcb.com and experience the difference of working with a leader in the PCB manufacturing industry.

Keep an eye for more news & updates on Gossips!