A PCBA or Printed Circuit Board Assembly is a critical part of many digital gadgets, including phones, computers, and TVs. Over the years, China has become considered one of the significant manufacturers of PCBAs.

China has been very good at producing those bendy PCBs, which could be in high demand.

This is because China uses a superior generation, has a professional staff, and can produce merchandise fast and at a low fee. In this text, we will look at how the pcba China enterprise has changed in China and the brand-new trends and technology that can permit it.

How PCBA Manufacturing Grew in China

China did now not end up a leader in the PCBA industry in a single day. It took years to get to this point. Here are a few reasons for China’s success.

Labor expenses are reduced by way of:

In the past, it turned into more inexpensive to hire in China than in lots of different countries. This has allowed corporations to keep cash by manufacturing their products in China.

Government Support:

The Chinese authorities subsidizes factories to help them spend money on higher technologies and construct better infrastructure which include roads, factories and strength supply.

Experienced team of workers:

China has invested closely in education and training, so there are masses of employees with the necessary capabilities to manufacture PCBs.

Best practices:

China has evolved a sturdy shipping infrastructure, communication infrastructure, and dependable strength. This lets centers be more efficient and meet global desires.

Critical Trends in PCBA Manufacturing in China

The PCBA design adjustments constantly. Here are a number of the most crucial traits shaping how China produces PCBAs these days:

1. Automation and Robotics

Many plants in China now use machines and robots to bring together PCBs. This makes the manner faster and more accurate. Robots can not work tirelessly and make fewer mistakes than human beings. This means better quality and quicker production.

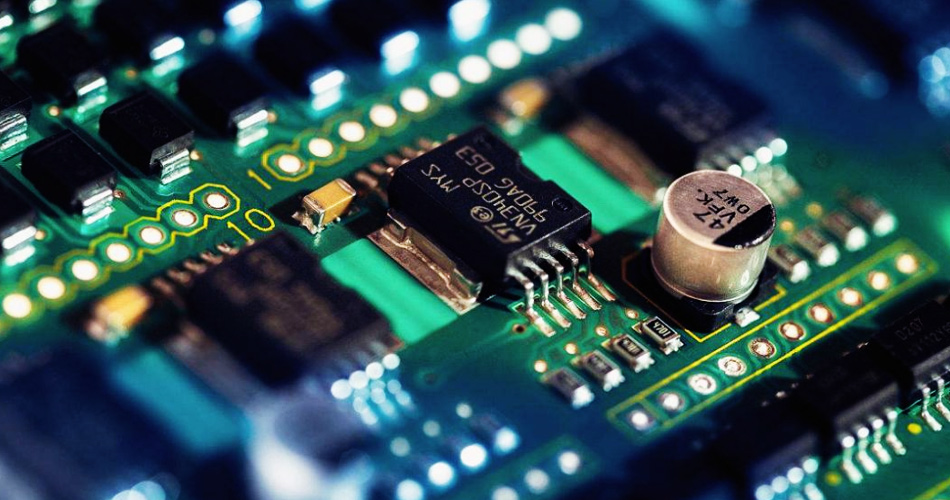

2. Surface Mounting Technology (SMT).

Surface Mount Technology (SMT) is a technique for mounting digital components without delay on a PCB floor. SMT saves money and time and permits smaller programs. Most Chinese factories use SMT, which allows them produce compact and advanced gadgets which include smartphones.

3. Minimal manufacturing

Today, digital devices are becoming smaller, like smartphones and wearable gadgets. This fashion, closer to miniaturization, requires more minor and cautious meetings. PCBA producers in China use new technologies to produce small, practical electronic gadgets without losing quality.

4. 5G Generation

The upward thrust of 5G technology additionally influences PCBA manufacturing in China. 5G networks require fast and advanced PCBs. Manufacturers are developing new methods to enhance the velocity and robustness of their products to keep up with the requirements of the 5G era.

5. Green Construction

Many Chinese businesses are focusing on inexperienced and environmentally pleasant manufacturing. This means using more harmful materials, including lead-unfastened solder, and locating methods to reduce recycling and waste. By doing this, they assist guarding the environment at the same time as generating excellent PCBs.

New Technologies in PCBA Manufacturing

China is leading the manner in using new technologies to improve PCBA performance. Here are a number of the most vital new capabilities:

1. Comprehensive testing and evaluation

Testing PCBAs is a crucial step to make sure that they are functioning nicely. China makes use of advanced trying devices, which include automatic optical inspection (AOI) and X-ray inspection in factories. These machines assist capture any mistakes or defects, ensuring that best the excellent PCBs are added to customers.

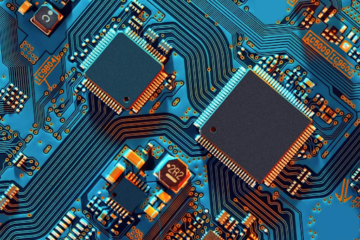

2. High Interconnectivity (HDI).

High-density interconnection (HDI) generation allows a couple of components to be packed onto smaller PCBs. This may be critical for gadgets like smartphones, which want to be small but mighty. China leads the manner in production HDI forums, supporting them in expanding advanced devices that are smaller and more excellent and efficient.

3. Flexible PCBs

Flexible PCBs can bend and twist without breaking. These are utilized in gadgets like smartwatches and other wearable electronics.

China has been superb at generating flexible PCBs, which might be in excessive demand.

4. Artificial Intelligence (AI)

AI is also supporting improved PCBA manufacturing in China. Factories are using AI to make production quicker and higher. AI can expect troubles, assist with excellent management, and make the system more efficient. This saves time and money at the same time as improving product first-class.

Conclusion

PCBA manufacturing in China has modified loads over the years. Lower exertions charges, authorities help, and new technologies have all helped China become a leader in this discipline. Trends like automation, miniaturization, and the 5G era are pushing the enterprise ahead, while improvements like bendy PCBs and AI are making manufacturing even higher.

By using these new developments and technologies, China is ready to maintain the assembly of the desires of the global electronics market. Whether it’s making smartphones, laptops, or wearable gadgets, China’s PCBA manufacturing is set to live strong and keep growing in its destiny.

Keep an eye for more news & updates on Gossips!