Thermoformed packaging is a widely used method for creating durable, lightweight, and customizable packaging solutions.

It involves heating a plastic sheet until it is pliable. Then, it is molded into specific shapes. This is called the thermoformed packaging process. This method has grown in popularity due to its efficiency and versatility, making it ideal for packaging products in various industries, from food to electronics.

This article will explore the best materials for thermoformed packaging. We’ll cover their performance and benefits. Whether you’re a manufacturer looking to improve your packaging or simply curious about the technology behind it, this guide will give you a comprehensive review of the most suitable materials available.

What Is the Thermoformed Packaging Process?

Before diving into the materials, it’s important to understand the basics of the thermoformed packaging process. This process involves heating plastic sheets to a high temperature until they are soft enough to be shaped into various forms.

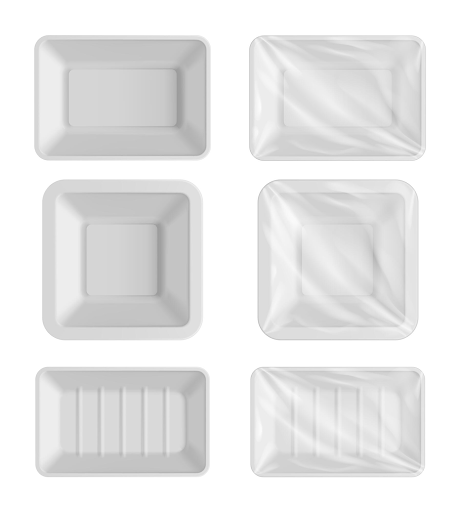

These forms could be trays, containers, or any other packaging design. The material is then placed in a mold and cooled, creating a strong and durable package that can withstand the rigors of transport and handling.

This process lets manufacturers create custom packaging for specific needs. This includes clear plastic food containers and specialized trays for medical devices. Now that you have a general idea of the thermoformed packaging process, let’s explore the materials that are often used.

Key Factors in Material Selection for Thermoformed Packaging

When selecting materials for thermoformed packaging, several factors come into play:

Material Durability and Strength

When it comes to protecting products during transit, durability is crucial. Traditional plastics like PET (Polyethylene Terephthalate) and HDPE (High-Density Polyethylene) are strong. They can endure the rigors of shipping. However, newer materials like bioplastics are also showing promising results in terms of durability.

Clarity and Transparency

For retail packaging where product visibility is key, use clear, transparent materials. PETG (Polyethylene Terephthalate Glycol) is preferred. These materials showcase the product effectively while maintaining structural integrity.

Barrier Properties

Certain products require protection from moisture, gases, or UV light. Materials like APET (Amorphous Polyethylene Terephthalate) and PP (Polypropylene) have great barrier properties. They extend the shelf life of perishables and keep products fresh. These materials also help to prevent the transfer of odors and flavors between packaged products.

Environmental Impact

In today’s world, sustainability is a top priority for many consumers. That’s why thermoforming companies are using eco-friendly materials. These include PLA (Polylactic Acid) and biodegradable plastics. These materials are as strong and protective as traditional thermoforming plastics. But, they have a lower environmental impact.

Cost-Effectiveness

Packaging can be a big expense for businesses. So, cost-effectiveness is key. PVC (Polyvinyl Chloride) and PE (Polyethylene) are cheap and common. So, they are a good choice for bulk packaging.

Customization Options

Technology has advanced. Now, packaging materials can be endlessly customized to suit each company’s unique needs. By printing logos and designs, and adding features like tear strips and easy-open packaging, businesses can create a custom package that reflects their brand.

Consumer Safety

Packaging plays a vital role in ensuring the safety of products and protecting consumers from potential harm. BPA-free plastics protect against harmful chemicals. Tamper-evident seals assure consumers that products are untampered with.

Common Materials Used in the Thermoformed Packaging Process

When it comes to thermoformed packaging, the choice of material is crucial. Each type of plastic used in the process has its own set of properties, advantages, and limitations. Here’s a breakdown of some of the most commonly used materials.

PET (Polyethylene Terephthalate)

PET is widely used in thermoformed packaging due to its clarity, impact resistance, and recyclability. It is suitable for various applications including food trays, blister packs, and consumer electronics packaging.

PET is frequently used in the thermoformed packaging process for products that require visibility and protection. Common uses include food packaging, medical devices, and retail clamshells. Thermoforming companies like https://www.andex.net/thermoform-trays/ provide thermoformed trays using high-quality PET, which are ideal for keeping products safe and visible.

PVC (Polyvinyl Chloride)

PVC is valued for its versatility and cost-effectiveness in thermoformed packaging. It has good impact resistance and barrier properties. So, it suits:

- medical packaging

- electronic components

- consumer goods

However, PVC has come under scrutiny due to its potential negative impact on the environment.

PETG (Polyethylene Terephthalate Glycol)

PETG combines the clarity of PET with enhanced durability and chemical resistance. It is often chosen for premium retail packaging where aesthetics and product visibility are critical. PETG is also widely used in medical and pharmaceutical packaging due to its hygienic properties.

APET (Amorphous Polyethylene Terephthalate)

APET has great barrier properties against moisture and gases. So, it is ideal for food packaging, especially for fresh produce and ready-to-eat meals. It provides superior protection while maintaining product freshness and extending shelf life. APET is also commonly used for blister packaging in the pharmaceutical industry.

CPET (Crystalline Polyethylene Terephthalate)

CPET is a high-performance material. It can withstand extreme temperatures and thermal shock. This makes it ideal for use in microwaveable food trays, as well as oven and freezer-safe containers. Its durability also makes it suitable for reusable packaging solutions.

PP (Polypropylene)

PP is flexible, lightweight, and heat-resistant. So, it is good for:

- microwaveable food containers,

- cosmetic packaging

- automotive parts

PP’s versatility in thermoformed uses is due to its ability to endure different temperatures and impacts.

RPET (Recycled Polyethylene Terephthalate)

RPET is derived from recycled PET bottles and offers similar properties to virgin PET. It supports sustainability initiatives. It reduces plastic waste while keeping high clarity and strength. RPET is used in food and drink packaging. It promotes eco-friendly practices in the packaging industry.

PLA (Polylactic Acid)

PLA is a bioplastic made from renewable resources such as cornstarch or sugarcane. It is compostable in an industrial setting. It has good moisture and gas barrier properties. PLA is used in sustainable packaging solutions for food service items and consumer products.

Choosing the Right Material for Thermoformed Packaging

In conclusion, the right materials for thermoformed packaging process are vital. They optimize product protection, presentation, and sustainability. Manufacturers can find options to improve their packaging. They can prioritize clarity, barrier properties, eco-friendliness, or durability.

Why stop now? Click through and explore our site-your next great discovery is just a scroll away!

Keep an eye for more latest news & updates on Gossips!