Pneumatic cylinders have indeed been the primary workhorses of manufacturing and engineering industries since the bygone era, or more precisely, they have been the necessity for the automated system as the primary drive mechanism. Thus, the development of pneumatic cylinders can be viewed as a reflection of technological progress as this device is an essential part of numerous industries. This guide will also show how suppliers of pneumatic systems have led this change and expanded the ability of these mighty systems.

Pneumatic cylinders

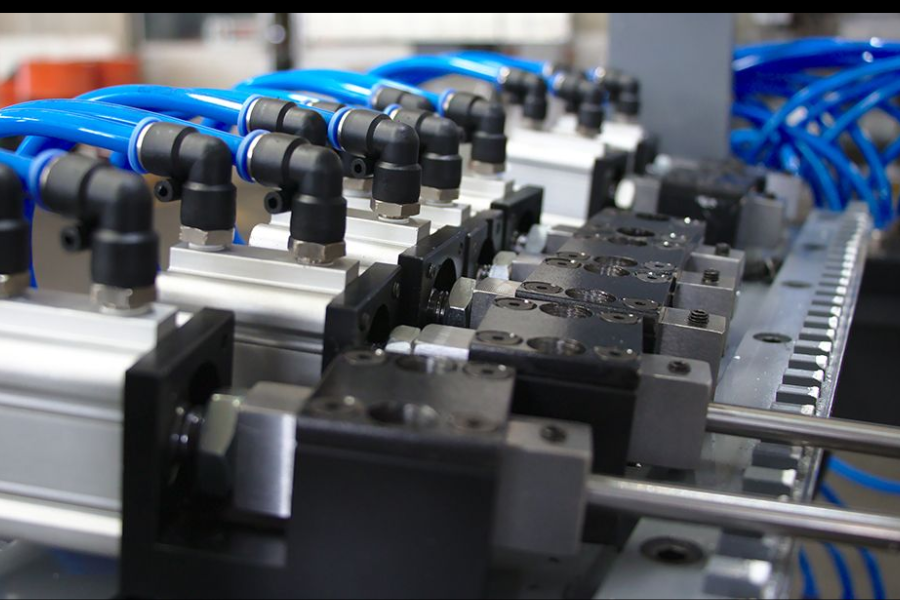

It is thought that pneumatic cylinders started being used in the early 1900s with very basic cylinders that could only be used for pushing and pulling. Such early cylinders were large, clumsy and had little provisions for controlling the robots, this was especially because initial robots were mainly industrial. Later on, the suppliers of pneumatic system understood a direction of the market towards higher levels of technology, and thus they contributed to the development of superior materials and manufacturing processes that fortified the pneumatic cylinders.

Technology Advancements

Pneumatic cylinders are one of the areas where modern material science has drastically changed the possibilities of the development of a broad variety of equipment. Materials like stainless steel and aluminum were incorporated by the pneumatic system suppliers to work on the lightweight yet durable cylinders as well as the corrosion protection of the same. Also, the emergence of better sealing material enhanced the efficiency and durability of cylinders for use in various conditions.

Electronics and Automation

One major advancement developed was the incorporation of electronics and automation into pneumatic cylinders. Many current pneumatic cylinders are fitted with feedback elements and other electronics which make it possible to position the cylinder with great accuracy and control its speed, opening up a myriad of uses for it. Pneumatic system suppliers have collaborated with pneumatic cylinder companies to integrate these technologies, ensuring that cylinders can be easily incorporated into automated systems.

Primary Function

Indeed, software is a critical component that has an increased role in the working of a pneumatic cylinder. Modern software tools make it possible to monitor the flow of air, its pressure and the direction it takes, and this increases the controllability, as well as the consistency of the process. Many suppliers of pneumatic systems also provide software for the special needs of industries that can be easily adjusted and control the pneumatic systems.

Future Trends

Therefore, the development of pneumatic cylinder technology lies in the deep integration with digital technology and the IoT. Currently, pneumatic system manufacturers are on the lead for designing brighter cylinders that can have prior information on when they are due for service, fine-tune themselves as well as interact with the other attachments, which are in a pneumatic system. Such improvements hold the strong potential to advance pneumatic cylinders’ dependency and performance flexibility even more.

To sum up, it is possible to state that the pneumatic cylinder technology development is the evidence of the continual progress, work, and contribution of pneumatic system suppliers and pneumatic cylinder firms. Starting from truly mechanical components and moving to significant parts of current automation, pneumatic cylinders remain a tool that evolves and responds to the dynamically changing needs of global industries. With the development of modern technology, pneumatic cylinders will have even more areas to be used, thus influencing the industrial automation zone.

Keep an eye for more news & updates on Gossips.Blog!