Introduction:

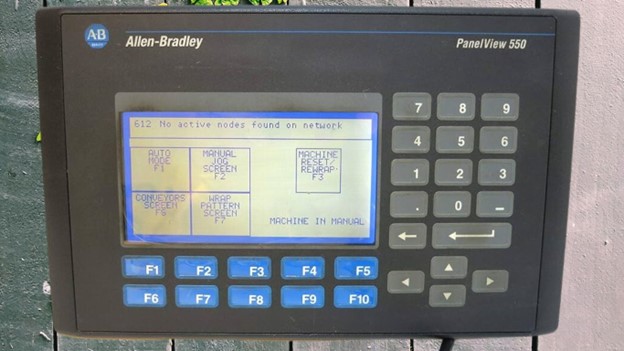

In the realm of industrial automation, the Allen Bradley 2711-K5A2L1 PanelView stands as a beacon of innovation and efficiency. Developed by Rockwell Automation, this Human-Machine Interface (HMI) device represents a cornerstone in modern manufacturing, offering a myriad of features designed to enhance control, visualization, and connectivity in industrial settings. In this detailed article, we embark on a journey to uncover the intricacies of the 2711-K5A2L1 PanelView, examining its technical specifications, diverse applications, and the myriad benefits it brings to industrial operations worldwide.

Technical Specifications and Features:

At the heart of the Allen Bradley 2711-K5A2L1 PanelView lies a wealth of cutting-edge features meticulously crafted to meet the demands of industrial automation. Here’s a closer look at its technical specifications:

- Display and Resolution: The PanelView boasts a vibrant color touchscreen display, offering an immersive visual experience with its high-resolution capabilities. Whether it’s monitoring critical parameters or configuring control settings, operators benefit from crystal-clear graphics and precise touch response.

- Communication Interface: Connectivity is paramount in today’s interconnected industrial landscape, and the 2711-K5A2L1 PanelView excels in this regard. Equipped with Ethernet and serial ports, it seamlessly integrates with a wide array of automation devices, PLCs (Programmable Logic Controllers), and industrial networks, facilitating real-time data exchange and remote monitoring capabilities.

- Memory Capacity: To accommodate the storage of application files, configurations, and historical data, the PanelView offers generous onboard memory capacity. This ensures seamless operation and data retention, even in the most demanding industrial environments.

- Durability and Enclosure: Industrial environments can be harsh and unforgiving, but the 2711-K5A2L1 PanelView is built to withstand these challenges. Encased in a rugged enclosure, it offers protection against dust, moisture, vibration, and temperature fluctuations, ensuring long-term reliability and uptime.

- Software Compatibility: The PanelView is supported by Rockwell Automation’s industry-leading software suite, including FactoryTalk View Studio, facilitating easy development, customization, and maintenance of HMI applications. This compatibility ensures seamless integration into existing automation infrastructures and enhances workflow efficiency.

Applications Across Industries:

The versatility of the Allen Bradley 2711-K5A2L1 PanelView makes it indispensable across a wide spectrum of industries. Here are some notable applications:

- Manufacturing: From automotive assembly lines to consumer goods production facilities, manufacturers rely on the PanelView for real-time monitoring of production processes, equipment status, and quality control parameters. Its intuitive interface empowers operators to optimize production efficiency and respond swiftly to changing demands.

- Oil and Gas: In the oil and gas sector, where operational safety and efficiency are paramount, the PanelView plays a crucial role in monitoring and controlling drilling operations, pipeline networks, and refining processes. Its robust design and reliable performance ensure uninterrupted operation in challenging environments.

- Pharmaceuticals and Life Sciences: Compliance with stringent regulatory requirements is non-negotiable in the pharmaceutical and life sciences industries. The PanelView facilitates adherence to industry standards by providing comprehensive process visualization, batch management, and data logging capabilities, thereby ensuring product quality and patient safety.

- Food and Beverage: In food processing and beverage manufacturing facilities, maintaining hygiene standards and product quality is imperative. The PanelView aids in recipe management, batch tracking, and compliance documentation, helping operators achieve consistency and traceability in production processes.

- Water and Wastewater Management: Water treatment plants and wastewater management facilities rely on the PanelView for monitoring critical parameters such as flow rates, pressure levels, and chemical dosing. Its intuitive interface and alarm management features enable operators to swiftly identify and address operational issues, ensuring uninterrupted supply and environmental compliance.

Benefits and Advantages:

The adoption of the Allen Bradley 2711-K5A2L1 PanelView offers a multitude of benefits to industrial enterprises:

- Enhanced Productivity: By providing operators with intuitive access to real-time data and control functionalities, the PanelView empowers them to make informed decisions swiftly, thereby optimizing productivity and minimizing downtime.

- Improved Operational Efficiency: The seamless integration with automation devices and software platforms streamlines workflow processes, reduces manual intervention, and enhances overall operational efficiency.

- Enhanced Safety and Compliance: With its comprehensive alarm management features and adherence to industry standards, the PanelView contributes to a safer working environment and ensures compliance with regulatory requirements.

- Reduced Total Cost of Ownership: The durability and reliability of the PanelView translate into reduced maintenance costs, lower downtime, and extended equipment lifespan, offering a favorable return on investment over the long term.

- Future-Readiness: As industries evolve and technology advances, the PanelView remains at the forefront of innovation, with firmware updates and compatibility enhancements ensuring its relevance and effectiveness in future industrial scenarios.

Conclusion:

In conclusion, the Allen Bradley 2711-K5A2L1 PanelView embodies the pinnacle of excellence in industrial Human-Machine Interface technology. With its advanced features, robust construction, and versatile applications, it continues to redefine the standards of efficiency, reliability, and connectivity in industrial automation. As businesses strive to adapt to evolving market dynamics and embrace digital transformation, the PanelView remains a trusted ally, empowering them to navigate the complexities of modern manufacturing with confidence and precision.

Stay in touch to get more updates & news on Gossips!